Although a business or balanced scorecard is not a quality control tool, we see among users of BSC Designer that many professionals apply the KPI scorecard and specifically use a Balanced Scorecard approach for ongoing quality control. In this article I summarize some of the best practices that I can recommend according to case studies that we did with our clients. Feel free to share your thoughts and experience about quality indicators on a scorecard in the comments section.

1. Business context comes first, then come indicators

Before you start thinking about the quality indicators, analyze your business context:

- Why do you need to measure the quality?

- What aspects of the quality are important to your customers?

- How exactly the company is planning to achieve current business goals?

- What quality-related problems need more attention?

- What are the business challenges of your company right now?

The answers to these questions will help you to align your quality indicators to the specific business problems. In this way you will start defining your “quality strategy.” Strictly speaking, there is no separate quality strategy, but an idea of the quality can be integrated into other generic strategies. For example, if we are talking about Product Leadership as a strategy, then the defect rate might be on the scorecard. If executives chose to follow a Customer Intimacy strategy, then a “First time resolution rate” might work as an indicator aligned with one of the business objectives from the “Customers” perspective.

![Business goals for quality control]()

In BSC Designer: go to the “Business goals” tab. There you can formalize your business goals and objectives, specify cause-and-effect connections between them. Later you can align KPIs with these goals and visualize them on the map.

2. Visualize your processes

Quality control or speaking more generally, quality assurance, is not only about having a set of indicators and reporting them. The idea is to have an understanding of the process, its strong and weak points, and trying to prevent possible quality issues. One needs to do a regular analysis of the quality challenges, their reasons and possible solutions. The result of this analysis needs to be formalized in the form of a flow chart.

![Visualize your process on quality process map]()

In BSC Designer: go to the “Strategy Map” tab, create a new map and use it to visualize your process. Later you will be able to visualize some KPIs directly on this map.

3. Balance between lagging and leading indicators

Have a look at the flow charts created in the previous step. On each step there is some input used and some result produced according to the defined standards. You can have quality indicators associated with those control points.

There might be leading or lagging indicators. Lagging indicators tell you a story of what has happen, this information is useful, but you are just observing what happened and you cannot change anything about that. In contrast, leading indicators reflect inputs that influence the process. On your scorecard you need to have both – leading and lagging indicators.

In BSC Designer: from the viewpoint of calculations, lagging and leading indicators are the same, the difference is in their business meaning that you provide as a user.

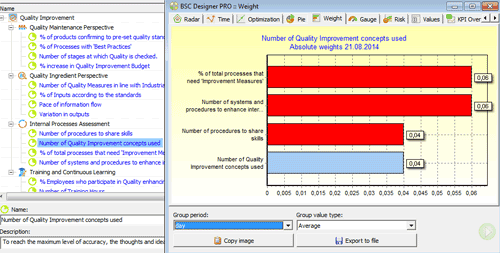

4. What are the most important indicators?

You answer: “All of them are important!” The question is: are all of them equally important? Reducing defects number from 0,01% to 0,001% might slow down the whole production system, while your clients were happy with a 0,01% defect rate, and for them the parameter of specific product function is much more important. You need to find a balance and reflect the differences between how important each of the indicators on your scorecard are.

![The weight of the most important quality KPIs]()

In BSC Designer: you have a weight property for an indicator. Check out an article that explained how to use it.

5. What is the performance of an indicator?

Let’s say you have 1% defect rate, then you optimized the process and achieved a 0,1% defect rate, finally, after an introduction of additional quality measures you got a 0,01% defect rate on average.

My question is: how was the performance of the respective quality indicator changed? Was it improved 10 times, and then again improved 10 more times? Not necessarily! From a business viewpoint clients might be unhappy with a 1% defect rate, and really happy when you have a 0,1% defect rate, and achieving a 0,01% defect rate may not have make any visible difference for them.

In real life some indicators have a linear performance function (you improve the value of an indicator 10 times and the performance improves 10 times), or the performance of an indicator might grow slowly in the beginning and then the function converts into an almost flat line, meaning that further improvements don’t improve the end performance. Remember this when you design your indicators and set targets for them.

![The performance of quality indicator decreases linearly with the increase of the value]()

In BSC Designer: there is an “Optimization” drop list, where you can change linear optimization function to a more relevant one for the measured aspect of the quality.

6. The total score of the quality scorecard

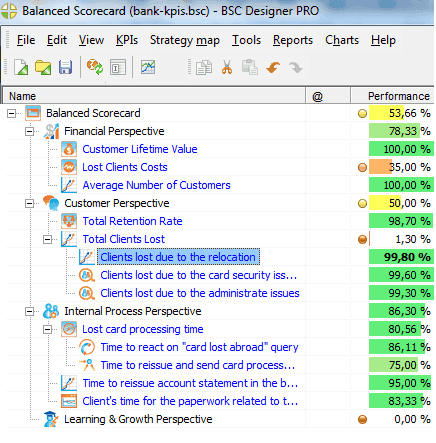

When you have 50+ indicators on your quality scorecard, each with its own performance function, benchmarks, values, and weights, then theoretically you can calculate the performance of each category and then the performance of the whole scorecard. As a result you will have a single number (in this case we might call it a “quality score”).

I know some top managers ask for a single quality score, but in the most cases it won’t make any sense, as this number aggregates too much data. It looks nice in the reports, but it won’t give any meaningful information for a top manager. The better option is to group indicators into categories and report the performance of each category.

![The total score of quality scorecard in BSC Designer]()

In BSC Designer: the program can calculate the performance figures for a container and for the whole scorecard, but the end usage is up to you.

7. Plan you actions

Be sure that you have (preferably in writing) some plan aligned to each quality indicator. What will you do if this indicator gets into the red zone? Are there any routine procedures associated with this indicator? How often do you need to revise this indicator? Who is responsible for an indicator?

![Initiatives and action plans for KPIs on quality scorecard]()

In BSC Designer: select an indicator or business goal, click “Initiatives” button, attach some relevant documents, choose a person responsible, and specify required update interval for an indicator.

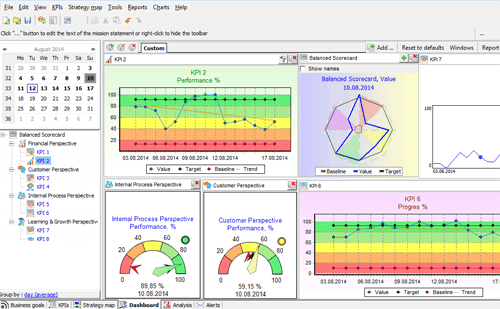

8. Build a quality dashboard

Dashboards help to visualize quality indicators. For some of them you will need to use a gauge-style chart, for others the best option is to display time chart with a trend line. A well designed dashboard will give you a top level view. Use it together with indicators visualized on the map. For more dashboard-related ideas, check out Dashboards Insight.

![Put quality KPIs on a dashboard]()

In BSC Designer: you can create a number of dashboards to visualize your indicators or business goals there.

9. Track the trend

Even if you check your indicators regularly you might miss out on a negative trend. For that purpose track indicators’ value for longer periods of time. For example, taking a 3 month period as a base for calculations you might see that an indicator is trending into a red zone. This will serve as an excellent early-warning signal for your team.

![Trend analysis of quality-related KPIs]()

In BSC Designer: “Time” chart has a trend line on it. Also, you can use “Forecast Analysis” on “Analysis Tab” to forecast indicators’ value.

10. Make sure you get bad news early

If some quality indicator has gotten into the red zone and this indicator is critical for the ultimate quality (if it is not, why is it on your quality scorecard?), then make sure that all of the stakeholders get a notification about the problem immediately.

![Get quality alerts early]()

In BSC Designer: on “Alerts” tab one can setup alerts that will be sent to the person responsible, or to the manager if an indicator is in the red zone.

General recommendations about quality metrics

On the Internet you might find some ready-to-use quality metrics, like these packs. Be careful about using these indicators, they aggregate some best practices about measuring quality, but your business does not necessary need them. The best approach is to pass through the steps 1-3 as described above and create indicators that are specific for your business.

What approach to quality indicators do you use in your company? What are your favorite quality KPIs?